Continuous Industrial Rotary Vacuum Dryer With Blades

Product Description

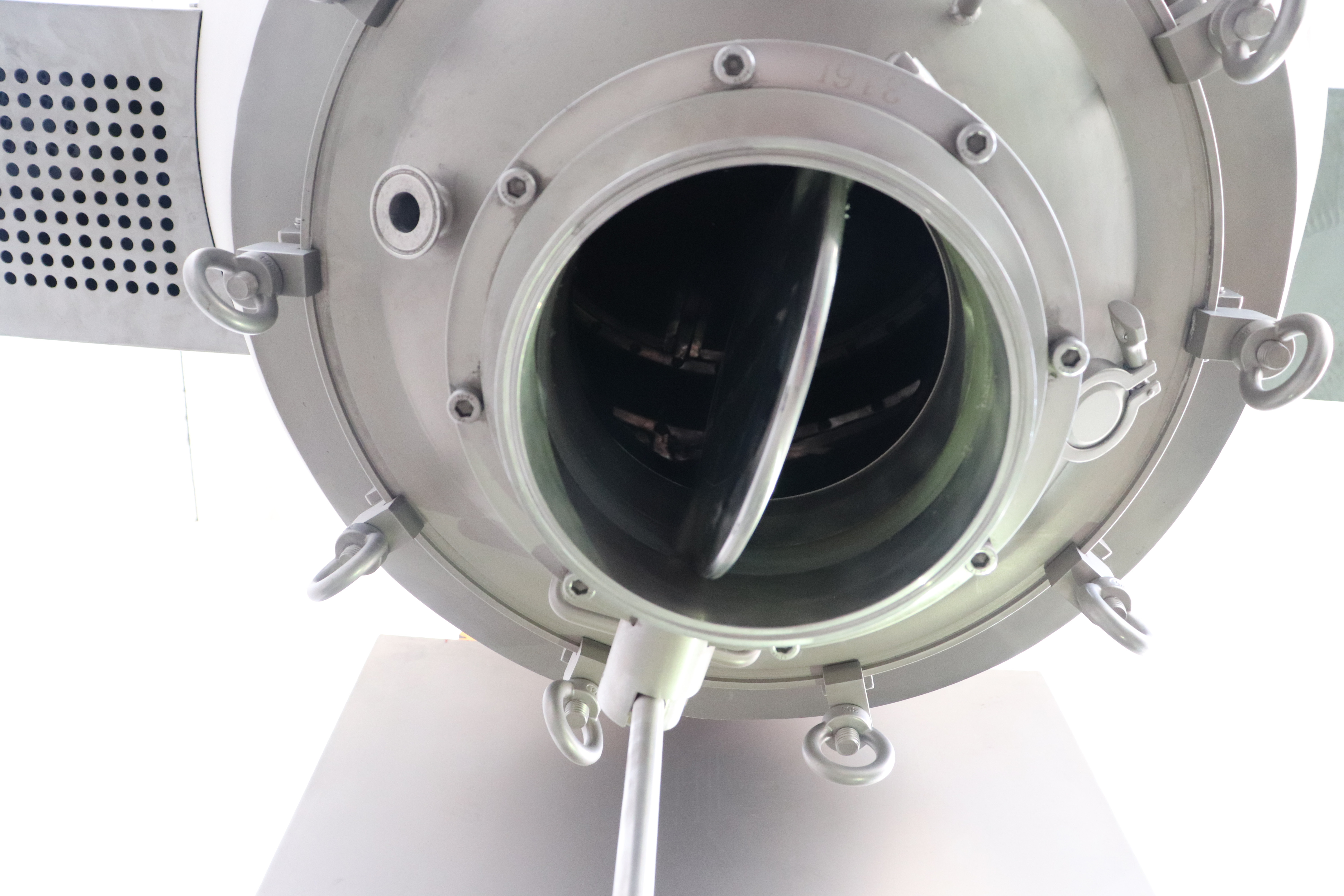

Multifunctional drying unit with blades

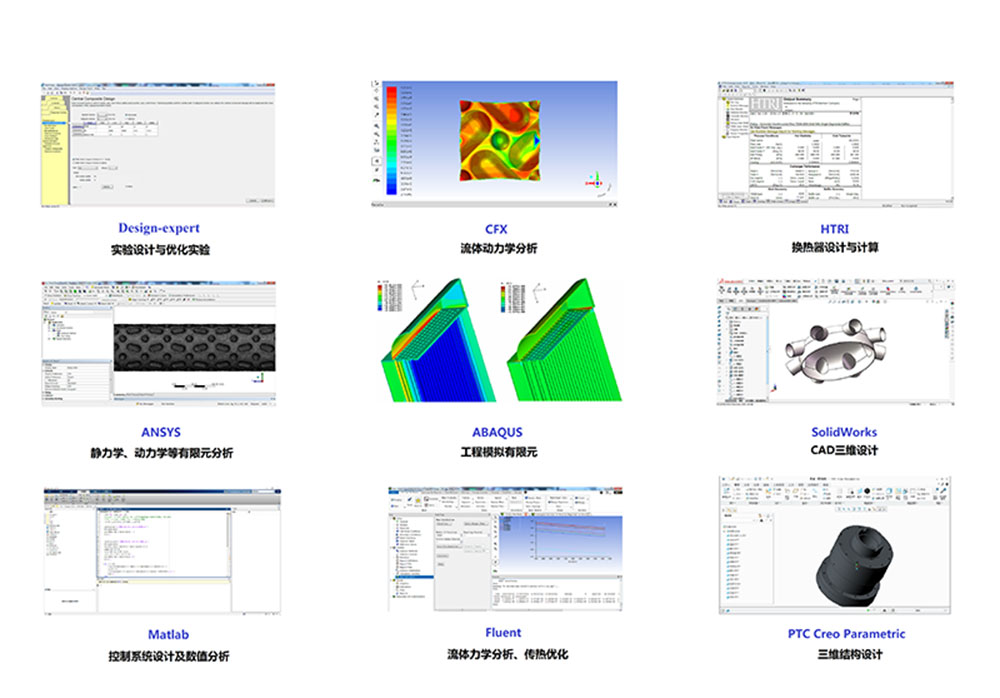

➤2. Filtering stage

Rotate the container for 180 degrees and turn the cone with the filteringplate downward. Connect the bottom of this cone with a vacuum deviceand complete the separation of filter cake and mother liquid

➤3. Washing stage

➤3. Washing stage

➤4. Drying stage

Product Details

Technical Parameter

| Total Capacity | Loading quantity | power of the lender | Rotate speed of dryer(R/min) | Area of condenser matches |

| 500L | 250L | 0.75kw | 0-5rpm/min | 7㎡ |

| 750L | 350L | 0.75kw | 0-5rpm/min | 7㎡ |

| 1000L | 350L | 1.1kw | 0-5rpm/min | 10㎡ |

| 1200L | 600L | 1.1kw | 0-5rpm/min | 12㎡ |

| ... | ... | ... | .. | .. |

| 10000L | 5000L | 1.5kw | 0-3.2rpm/min | 100㎡ |

Our Advantage

| | High concentricity of two axes of equipment, 3000L with the concentric degree ≤ 0.16mm, 3000L-5000Lconcentricity ≤ 0.20mm,5000L - 18000L concentricity ≤0.25 mm. More stable operation, better sealing performance, longer service life |

| New advanced airtight technology, vacuum ≤ 030Pa, improve product quality, can be used for aseptic grade product production | |

| Clean CIP online (if configured) to reduce labor and equipment pollution | |

| Online sterilized SIP (if configured), capable of producing sterile products | |

| Online weighing system (if configured) eliminates the need for weighing after secondary material transfer to reduce labor force and improve measuring accuracy | |

| Polishing precision up to 0.014μm, (if configured), easy to clean equipment, prevent material sticking to the wall | |

| Double taper with knife (if available) to prevent pilling of sticky materials during drying | |

| The first in China, the double cone produced in 1978, is still in use by users, with reliable performance. With nearly 40 years of experience, it has produced no less than 1000 sets |

1. Multifunctional “Three in One” (filtering, washing and drying)

3. Sterile double-cone dryer

4. Rake Vacuum Dryer /Paddle Vacuum Dryer

5. Plate-fin Heat Exchanger

➤Our advantage

1. Special Equipment: Pressure Equipment, Equipment made of anti-corrosion materials, Sterile Equipment

Equipment made of anti-corrosion materials includes: anti-corrosion lining plastic/ PTFE/ enamel,

Ti/HC22/Mone11

2.Customized Design: Double-Cone in 20L-20m³

Rake Dryer (with mechanical seal) in 16 m³

DN300-DN600 “Three in One”

3.Design/Calculation Software

➤Scope of business

1. On-site Inspection

2.Technical Innovation Plan for Equipment Technical Improvement Plan for Equipment’s Structure Optimization Fast and Effective Solution to Equipment Malfunctions Highly Efficient and Precise On-site Construction Service Commitment to a Deadline in Customization A Full Range of long-term on-site technical maintenance service

3. Maintenance

4. Technical Solutions

5.On-site Testing and Training

6. Spare Parts

Product Categories : Vacuum Drying Equipment > Multifunctional drying unit with blades