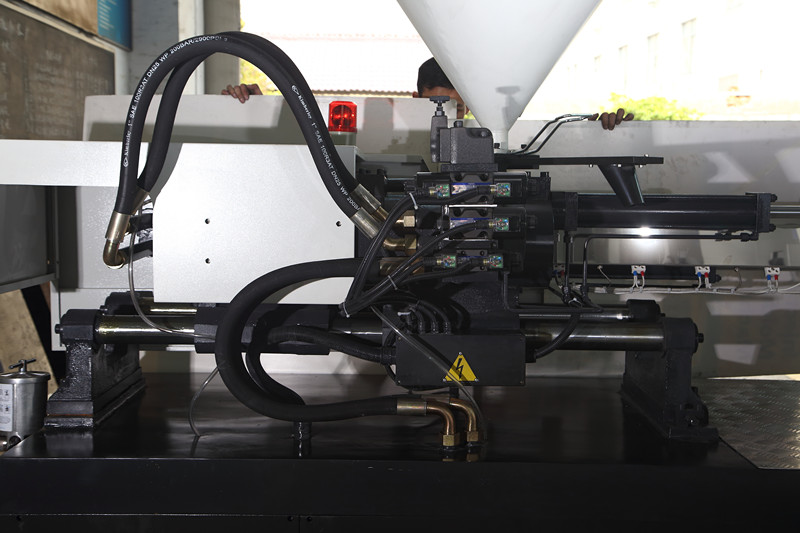

high capacity plastic fork knife spoon cup making machine

Product Description

Product Description

Product Paramenters

SZ-3000A INJECTION UNIT | ||||||||

ITEM | UNIT | VALUE | ||||||

SCREW DIAMETER | mm | 60 | 65 | 70 | ||||

SCREW L/D RATIO | L/D | 22.7 | 21 | 19.5 | ||||

Theoretical Shot Volume | cm^3 | 848 | 995 | 1154 | ||||

SHOW WEIGHT(PS) | g | 772 | 905 | 1050 | ||||

INJECTION PRESSURE | Mpa | 207 | 176 | 152 | ||||

THEORETICAL INJECTION RATE(PS) | g/s | 241 | 283 | 328 | ||||

PLASTICISING CAPACITY | g/s | 35.2 | 43.3 | 51.8 | ||||

SCREW TORQUE | N.m | 2530 | ||||||

MAX.SCREW ROTATE SPEED | r/min | 150 | ||||||

INJECTION STROKE | mm | 300 | ||||||

SZ-3000A CLAMPING UNIT | ||||

ITEM | UNIT | VALUE | ||

MAX.CLAMPING FORCE | KN | 3000 | ||

MAX.OPENING STROKE | mm | 590 | ||

SPACE BETWEEN TIE BARS | mm | 610*610 | ||

Mould HEIGHT | mm | 220-630 | ||

MAX.DAYLIGHT | mm | 1220 | ||

EJECTOR FORCE | KN | 70.6 | ||

EJECTOR STROKE | mm | 150 | ||

EJECTOR QUANTITY | 9 | |||

SZ-3000A OTHER | ||||

ITEM | UNIT | VALUE | ||

PUMP MOTOR POWER | KW | 30 | ||

PUMP PRESSURE | Mpa | 16 | ||

HEATING POWER | KW | 22 | ||

HEATING ZONE | 5 | |||

SIZE | m | 6.7*1.75*2.25 | ||

NET WEIGHT | t | 11 | ||

OIL TANK CAPACITY | L | 560 | ||

INTERNATIONAL DESIGNATION | 3000-1750 | |||

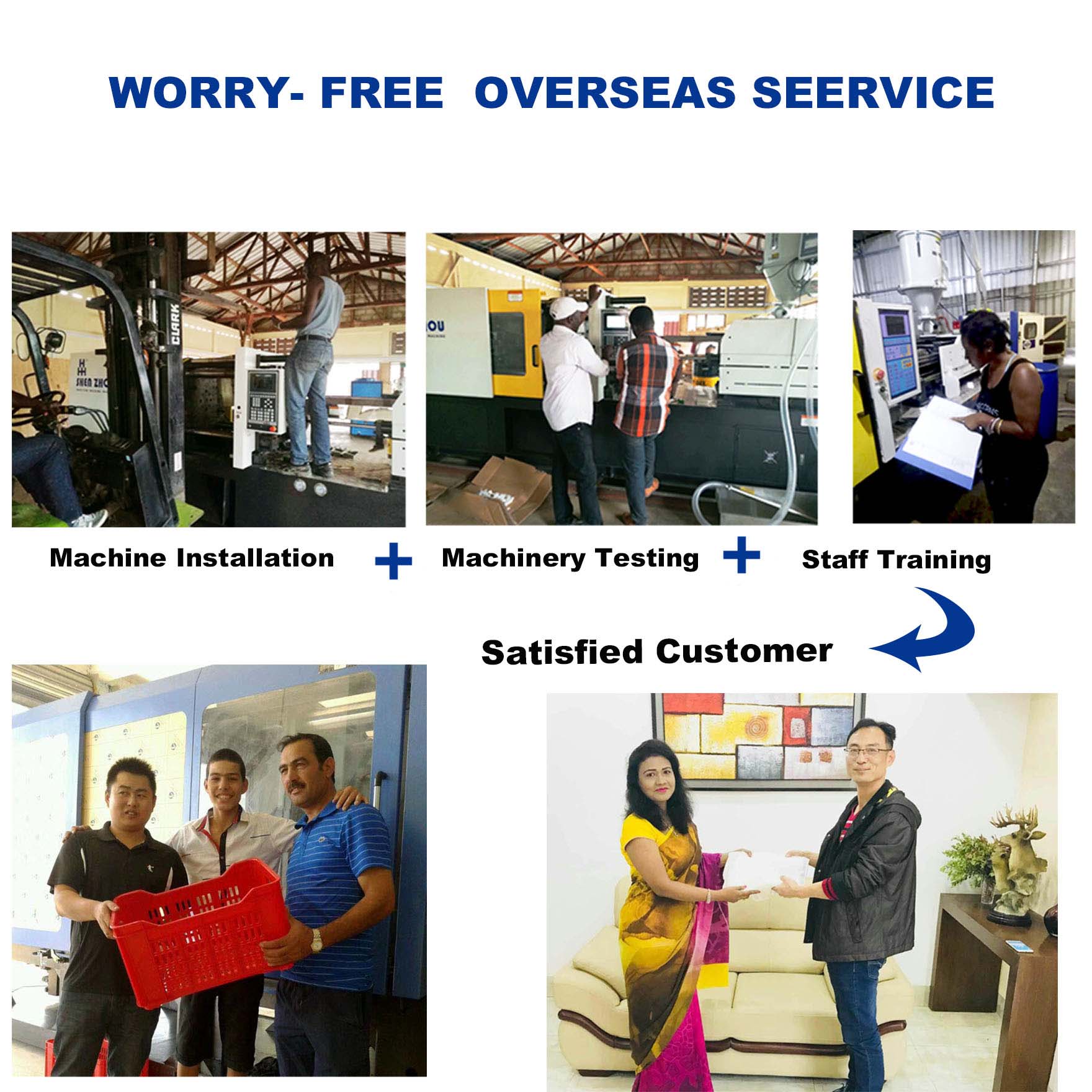

Why Choose Us

1. 20 years of professional injection molding machine and mold manufacturer, excellent quality, honest management 2. Continuous technological innovation, optimized product structure, longer service life 3. Lifetime maintenance of the product, 24 hours after-sales service 4. The main components are all world-renowned brands 5. Dedicated quality control department 6. Ex-factory price

Company Profile

SHENZHOU-Your trusted plastic processing partner

Our company - injection molding machine, blow molding machine, main blower, mold, computer embroidery machine professional manufacturer - located in the national new port city of Zhangjiagang City, Xizhang Town, close to the Yanjiang Expressway and 204 National Road, close to Shanghai, Nanjing, Suzhou, Wuxi Large and medium-sized cities such as Nantong have convenient transportation. The company has accumulated rich experience in manufacturing injection molding machines for many years, high standard design and precision processing, using imported famous brand hydraulic, electrical and sealing components, and fully creating SZ series automatic computer injection molding machine and peripheral supporting equipment, with its excellent quality and stability. The performance, superior price performance ratio, to the greatest extent to meet the interests and needs of customers.

Packing & Delivery

We will apply lubricating oil and spray anti-rust agent to the products before shipment, prepare enough spare parts, and confirm that they are fully fixed before shipment. We pay attention to details and hope to bring you a better experience.

Customer story

Old friend.

The client's name is Obed, from Tanzania. He is our old friend. We have been working with him for more than 15 years and we have established a deep friendship. At the beginning, Obed was our ordinary customer. After a period of mutual cooperation and understanding, he has become our technical representative in Tanzania and can provide various technical support to our customers in Tanzania. At the end of 2020, we will have 23 injection molding machines and a large number of molds sent to Tanzania.

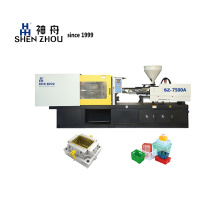

Large Orders.

The order is from Turkmenistan. A customer friend of ours bought 26 injection molding machines of various models and a large number of molds and Auxiliary Equipment at a time. After receiving the order, we attach great importance to it, speed up the operation of the workshop, and complete the scheduled tasks in advance. The picture shows a customer in Uzbekistan. We have a vast market in this region.

Government program.

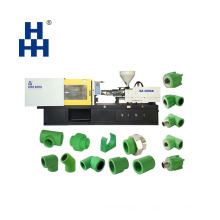

This project is a cooperation project between us and Ethiopian AG pipe fitting company in 2019. Our company started cooperation with Ethiopia long ago. We have delivered more than 15 injection molding machines and more molds to Ethiopia.

FAQ

1.Q:Are you a factory or trading company? A: Industry and Trade Integration, we supply the factory price with good quality, welcome to visit ! 2.Q:How does your factory do regarding quality control? A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end and we have a dedicated quality control department. 3.Q:What are your normal lead times? A:Our company typical lead times range from 25-35days after receipt of order.We also have independent venues and engineers to deal with more urgent orders, which can be shipped within 2 weeks. 4.Q:About the price? A:We will estimate the cost and provide you with the best price. We can guarantee you the best product quality and after-sales service at the same price. Old customers will enjoy more price concessions. 5.Q:How is your machine different from other businesses? A:We have optimized the overall layout of each part of the machine to make the machine run smoothly and have a longer service life. The fine parts have exclusive marks, which makes it more convenient for customers to replace parts and use. 6.Q:Where is your factory located? How can I visit there? A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China.All our clients,from home or abroad, are warmly welcome to visit us!

You are welcome to send us samples, we will customize high-quality machines for you!Best wishes for you!

Product Categories : Plastic Injection Molding Machine

Premium Related Products

Other Products

Hot Products

Mother and Baby Extruder Pelleting MachineUsed Production Line Plastic Recycling Machinery for GranulationHDPE PP Flakes Recycling Pelletizing Production Line/Granulating MachinePlastic Recycling Machinery Pet Film Pellet Making MachineWaste BOPP PE Film Recycling Plastic Granule Making Machine PriceWaste Pppe Plastic Film Recycling MachineXY-31 1120A three roller rubber calender machineSigma kneader double arms blending machinePET Bottle Washing Recycling LinePRE-220/250 Planetary PVC Pelletizing LinePP-R Pipe Extrusion Production MachinePVC Plastic Turbo Pulverizer MillSJL-350 Plastic Strainer Plastic filtering machine Plastic straining extruderPRE-190 Planetary Roller Extruder/high capacity for PVC granulePRE Extruder PVC Pelletizing LineNew design Three roll rubber sheet calender line