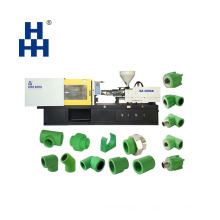

Used Plastic Granule Machine for PE PP Recycling

Basic Info

Model No.: SJ

Product Description

Model NO.: SJ Screw: Single-Screw Electromagnetic Heater: Electromagnetic Heater Computerized: Computerized Certification: CE, ISO9001:2008, SGS Electric Brand: Siemens, ABB, Rkc, Omron, Delta After-Sale Service: Supply Machine Installation and Training Delivery Time: Within 50 Workdays Warranty Period: 12 Months Packed: Film Packing Machine, with Wood Trademark: QUANTAI Origin: Zhangjiagang, Jiangsu, China Raw Material: PP, PE, ABS, PC, PA Inverter: Inverter Automation: Automatic Customized: Customized Condition: New Certificate: CE & SGS Capacity: 100kg/H-1000kg/H Color: Customized Recycling Material: PP, PE, ABS, PC, PA Machine: Plastic Granule Machine Specification: SJ30-200 HS Code: 84772010 Used Plastic Granule Machine for PE PP Recycling

This QT-SJ series plastic Pelletizing machines are mainly applied to pelletize Crushed (rigid) materials, bottle flakes & agglomerated films, etc.

This type Pelletizing Line has special screw design, effective degassing and filter (Hydraulic screen changer) system, with stable output and long service life.

Machines are highly-automatic, only need 2 workers for operating the whole pelletizing production line. One worker for controlling the Electric control panel, one for feeding materials and changing Hydraulic Screen Changer.

Plastic Granule Machine Applications:

Applicable plastic materials: PE, HDPE, LDPE, PP, BOPP etc

Material shapes: Bottle flakes, crushed film/bags and regrind material

Note: Depending on different material properties, various downstream equipments are needed.

Plastic Granule Machine Advantages:

1. Adopt double stage extrusion line with more stable output

2. CE Certificate

3. Long service life

4. Customized

5. Special designed side force feeder with high output for crushed film

6. Support installation and operation training at Buyer's plant

After-sales service:

Send engineers to install, test the machines and offer technology guidance and worker training at customers' factory.

Offer 12 months free maintenance and life long service. After the warranty period, spare parts will be provided at basic cost.

Build customers database. All machines are traceable.

Visit customers and make quality trace periodically and take customers' feedback into account during routine practices.

Speed up service and spare parts supply.

Contact us if you need more details on Used Plastic Granulation Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Recycling Machinery、Plastic Granulation. If these products fail to match your need, please contact us and we would like to provide relevant information.

This QT-SJ series plastic Pelletizing machines are mainly applied to pelletize Crushed (rigid) materials, bottle flakes & agglomerated films, etc.

This type Pelletizing Line has special screw design, effective degassing and filter (Hydraulic screen changer) system, with stable output and long service life.

Machines are highly-automatic, only need 2 workers for operating the whole pelletizing production line. One worker for controlling the Electric control panel, one for feeding materials and changing Hydraulic Screen Changer.

Plastic Granule Machine Applications:

Applicable plastic materials: PE, HDPE, LDPE, PP, BOPP etc

Material shapes: Bottle flakes, crushed film/bags and regrind material

Note: Depending on different material properties, various downstream equipments are needed.

Plastic Granule Machine Advantages:

1. Adopt double stage extrusion line with more stable output

2. CE Certificate

3. Long service life

4. Customized

5. Special designed side force feeder with high output for crushed film

6. Support installation and operation training at Buyer's plant

After-sales service:

Send engineers to install, test the machines and offer technology guidance and worker training at customers' factory.

Offer 12 months free maintenance and life long service. After the warranty period, spare parts will be provided at basic cost.

Build customers database. All machines are traceable.

Visit customers and make quality trace periodically and take customers' feedback into account during routine practices.

Speed up service and spare parts supply.

| Screw diameter | 30 | 45 | 65 | 90 | 100 | 120 | 150 | 60 | 180 | 200 |

| L/D | 18-42 | |||||||||

| Rotary speed(r/min) | 10-150 | |||||||||

| Capacity(kg/h) | 2- 40 | 10- 60 | 100- 150 | 180- 250 | 250- 350 | 300- 600 | 400- 750 | 800- 1000 | 1500- 2000 | 2000- 3000 |

Contact us if you need more details on Used Plastic Granulation Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Recycling Machinery、Plastic Granulation. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Rigid / Hard plastic recycling granulator > PP flakes/ regrind recycling granulator

Other Products

Hot Products

Mother and Baby Extruder Pelleting MachineUsed Production Line Plastic Recycling Machinery for GranulationHDPE PP Flakes Recycling Pelletizing Production Line/Granulating MachinePlastic Recycling Machinery Pet Film Pellet Making MachineWaste BOPP PE Film Recycling Plastic Granule Making Machine PriceWaste Pppe Plastic Film Recycling MachineXY-31 1120A three roller rubber calender machineSigma kneader double arms blending machinePET Bottle Washing Recycling LinePRE-220/250 Planetary PVC Pelletizing LinePP-R Pipe Extrusion Production MachinePVC Plastic Turbo Pulverizer MillSJL-350 Plastic Strainer Plastic filtering machine Plastic straining extruderPRE-190 Planetary Roller Extruder/high capacity for PVC granulePRE Extruder PVC Pelletizing LineNew design Three roll rubber sheet calender line