Multifunctional plastic PP PE recycle and pelletizer granulating line with high quality

Product Description

Company Brief Introduction - Jiangsu Xinrongplas Machinery Co., Ltd.

Top Plastic Machinery Manufacturer Since 1996.

Our main products are: plastic Pipe Extrusion Line and Plastic Recycling Machine.

The main products are popular in the domestic market,such as the East China market,Southwest market,Northeast market and Central China market.The products are also exported to international market,including Russia,Australia, Southeast Asia,Middle East,East Europe.Africa and other countries.

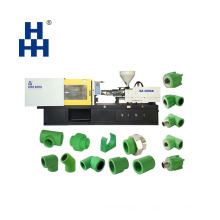

Final Products

PE,PP film Pelletizing.

PE PP film Pelletizing Line is used for PE PP soft material. As compactor is equipped, film in big size can enter into the machine directly, not need extra crushing process. Compactor is controlled by PLC and inverter, the temperature inside is stable. Cooling is by water which has better cooling effect. Customer can choose water ring hot cutting or strand pelletizing. Single stage or double stage pelletizing for choice.

Products Description

PE PP FILM PELLETIZING LINE.

1.All recycled materials can be produced after being sorted, broken and cleaned without drying, drying or drying. 2.From raw material crushing, cleaning, feeding to pelletizing, all are automated.

3.Make full use of the high-pressure friction continuous heating system to automatically heat production, avoid continuous heating, save electricity and energy.

4.The split automatic power distribution system is adopted to ensure the safe and normal operation of the motor.

5.The screw and barrel are made of imported high-strength and high-quality carbon structural steel, which is durable. 6.The appearance of the machine is beautiful and generous. Color and spray paint can be matched according to customer requirements.

4.The split automatic power distribution system is adopted to ensure the safe and normal operation of the motor.

5.The screw and barrel are made of imported high-strength and high-quality carbon structural steel, which is durable. 6.The appearance of the machine is beautiful and generous. Color and spray paint can be matched according to customer requirements.

Machine List | ||||||

1.0 | Belt Conveyor | 6.0 | Vibrating machine | |||

2.0 | Compactor | 7.0 | Dewatering Machine | |||

3.0 | SJ85/33 extruder | 8.0 | Silo | |||

4.0 | Hydraulic Screen changer | 9.0 | Electric control box | |||

5.0 | Water ring pelletizing | |||||

Machine Details

1.0 Belt conveyor

Used to convey material into next machine.

2.0 Compactor

Used to convey material into next machine.With metal detector to detect metals, when metal detected, belt conveyor will stop and alarm. After metal removed, belt will work again.

3.0 SJ85/33 extruder

To shred material into relative small sizes. Then feed into crusher to crush into smaller sizes. In this way, crusher will increase dramatically.

4.0 Hydraulic Screen changer

To crush material into small sizes. With water to clean material and cool blades during crushing.

5.0 Water ring pelletizing

Use to collect material together and convey to next machine.

6.0 Vibrating machine

Used to convey material into next machine.

7.0 Dewatering Machine

To convey material into next machine, also cleaning material at same time. The friction plates inside tank are made of special wear-resistant steel for durability.

8.0 Silo

To remove remaining impurities by water and high speed friction. The friction plates inside tank are made of special wear-resistant steel for durability.

9.0 Electric control box

To remove remaining impurities by water and high speed friction. The friction plates inside tank are made of special wear-resistant steel for durability.

Product Paramenters

Production Line Parameter (for reference only, can be customized) | ||||||||

Model | Capacity(kg/h) | Compactor Motor Power(kw) | First Stage Motor Power(kw) | Second Stage Motor Power(kw) | ||||

SJ90H | 150-200 | 37 | 55 | 15 | ||||

SJ100H | 250-350 | 55 | 90 | 30 | ||||

SJ120H | 350-450 | 75 | 110 | 37 | ||||

SJ150H | 500-600 | 90 | 160 | 45 | ||||

SJ180H | 750-850 | 110 | 200 | 75 | ||||

SJ200H | 850-1000 | 132 | 250 | 90 | ||||

Recommend Products

Plastic Recycling Machine

PET Bottle Washing&Recycling Line

Why Choose Us

Jiangsu Xinrongplas Machinery Co., Ltd.

Jiangsu Xinrongplas was established in 1996. The production experience is mature and rich. Among them, it has been exporting for more than 20 years, and more than 100 countries have exported. The annual export turnover is about 15 million US dollars. Our company's production base covers more than 50,000 square meters. , Modern office and production room more than 35,000 square meters, with experienced high-quality staff team, first-class equipment, perfect and effective quality assurance system, advanced and complete testing equipment.

Workshop.

We know the quality is the life of our company. Our company insists to manufacture all machine units by ourselves in order to control quality strictly by our quality inspectors. To implement this concept, we have built our own tooling and CNC workshop. Even if some parts from our certified supplier, our quality inspector will check these parts before entering into our warehouse.

Warmly welcome to visit our workshop, and sincerely hope we can have long term cooperation in near future!

Warmly welcome to visit our workshop, and sincerely hope we can have long term cooperation in near future!

Certificates & Patents.

International certification, National Certificate of equipment verification, and more than 30 invention patents.

Verification Certificates of equipments: ISO; CE Certificate , SGS, COC, TUV National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark registration,etc.

Exhibitions.

Verification Certificates of equipments: ISO; CE Certificate , SGS, COC, TUV National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark registration,etc.

Exhibitions.

FAQ

1) Are we manufacture or trade company?

We are manufacture,have 24 years' experiences in this field.

2) What kind machines we produce?

Our factory produce plastic pipes machines, plastic recycling machine.

3) What kind payment we accept?

Payment term like T/T, L/C.

4) How long we need to produce the machines?

According to different machine model and configuation, we need different time, like 40 days to 2 months.

5) Will the machine be delivered on time ?

Sure,we will deliver your machine up recieving the balance payment.

6) How about the machine quality?

Our machine quality is reliable.We select every parts on the machine strictly and production and installation is done by

professional workers.We test the each production step for the best machine.

7) How about the price?

You know ,the goods counts the the price.We select the best machine raw material such as siemens electrics,schneider and ABB etc.We will provide you the best machine with best price.

8) How long is your machine’s guarantee time?

One year

9) What can you provide for after sale service?

We can send engineers to your factory for installation and training.also 24 hours on-line service for you.

We are manufacture,have 24 years' experiences in this field.

2) What kind machines we produce?

Our factory produce plastic pipes machines, plastic recycling machine.

3) What kind payment we accept?

Payment term like T/T, L/C.

4) How long we need to produce the machines?

According to different machine model and configuation, we need different time, like 40 days to 2 months.

5) Will the machine be delivered on time ?

Sure,we will deliver your machine up recieving the balance payment.

6) How about the machine quality?

Our machine quality is reliable.We select every parts on the machine strictly and production and installation is done by

professional workers.We test the each production step for the best machine.

7) How about the price?

You know ,the goods counts the the price.We select the best machine raw material such as siemens electrics,schneider and ABB etc.We will provide you the best machine with best price.

8) How long is your machine’s guarantee time?

One year

9) What can you provide for after sale service?

We can send engineers to your factory for installation and training.also 24 hours on-line service for you.

Product Categories : Ungrouped

Premium Related Products

Other Products

Hot Products

Mother and Baby Extruder Pelleting MachineUsed Production Line Plastic Recycling Machinery for GranulationHDPE PP Flakes Recycling Pelletizing Production Line/Granulating MachinePlastic Recycling Machinery Pet Film Pellet Making MachineWaste BOPP PE Film Recycling Plastic Granule Making Machine PriceWaste Pppe Plastic Film Recycling MachineXY-31 1120A three roller rubber calender machineSigma kneader double arms blending machinePET Bottle Washing Recycling LinePRE-220/250 Planetary PVC Pelletizing LinePP-R Pipe Extrusion Production MachinePVC Plastic Turbo Pulverizer MillSJL-350 Plastic Strainer Plastic filtering machine Plastic straining extruderPRE-190 Planetary Roller Extruder/high capacity for PVC granulePRE Extruder PVC Pelletizing LineNew design Three roll rubber sheet calender line